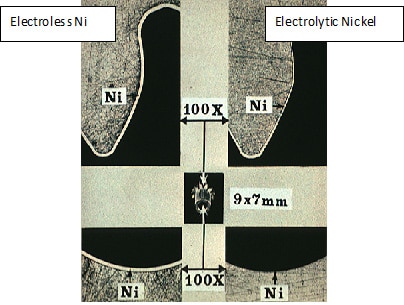

This means that instead of using an outside source of electricity like in the similar electroplating process the electroless nickel plating process uses a chemical bath to deposit a nickel phosphorous layer onto the metallic surface.

Electroless nickel plating aluminum process steps.

Electroless nickel phosphorus plating is a chemical process that deposits an even layer of nickel phosphorus alloy on the surface of a solid substrate like metal or plastic the process involves dipping the substrate in a water solution containing nickel salt and a phosphorus containing reducing agent usually a hypophosphite salt.

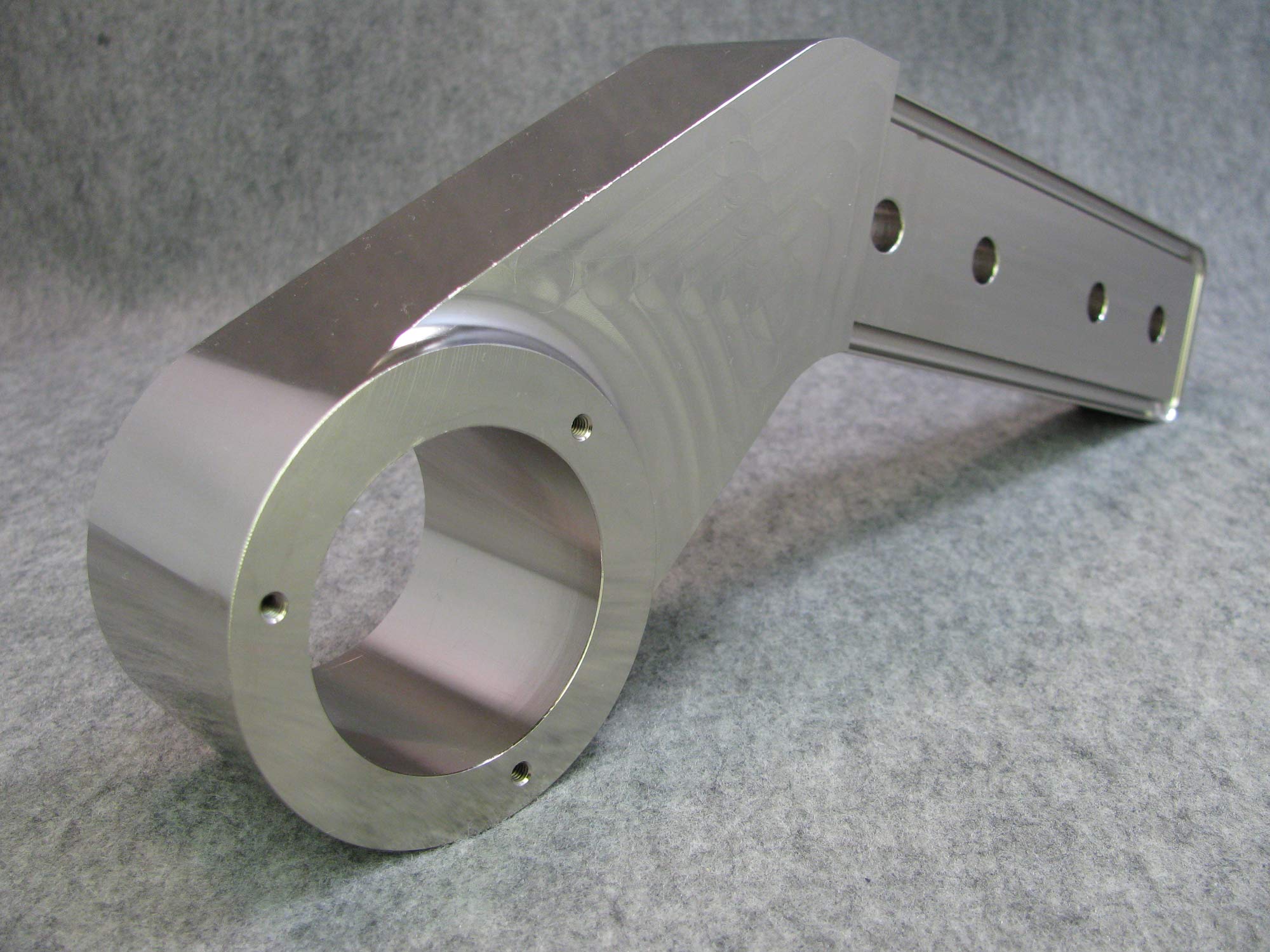

En plating is selected because of its ability to protect aluminum from hostile environments and to make a hard wear resistant surface that allows aluminum to be.

Electroless nickel is applied by heating the nickel bath to 195 f and then immersing the part to be plated into the bath for 15 60 minutes depending on the desired thickness.

Electroless nickel plating can be a simple and effective way of applying a nickel plate over steel iron copper brass zincated aluminum and copper alloys.

There is no need to pass an electric current through the chemical bath solution in order to initiate the plating process.

Electroless nickel plating tutorial.

Plating aluminum with electroless nickel is not difficult.

After this step the parts are treated with an alkaline dip and or an acid dip depending on the type of aluminum alloy being used.

The aluminum parts must be cleaned to remove greases oils and other soils.

The process of adding an electroless nickel plating to a metal surface is an autocatalytic chemical reduction.

Electroless nickel plating is a form of alloy treatment designed to increase resistance and hardness in a metal or plastic.

It is the most common version of electroless nickel plating.

.jpg)